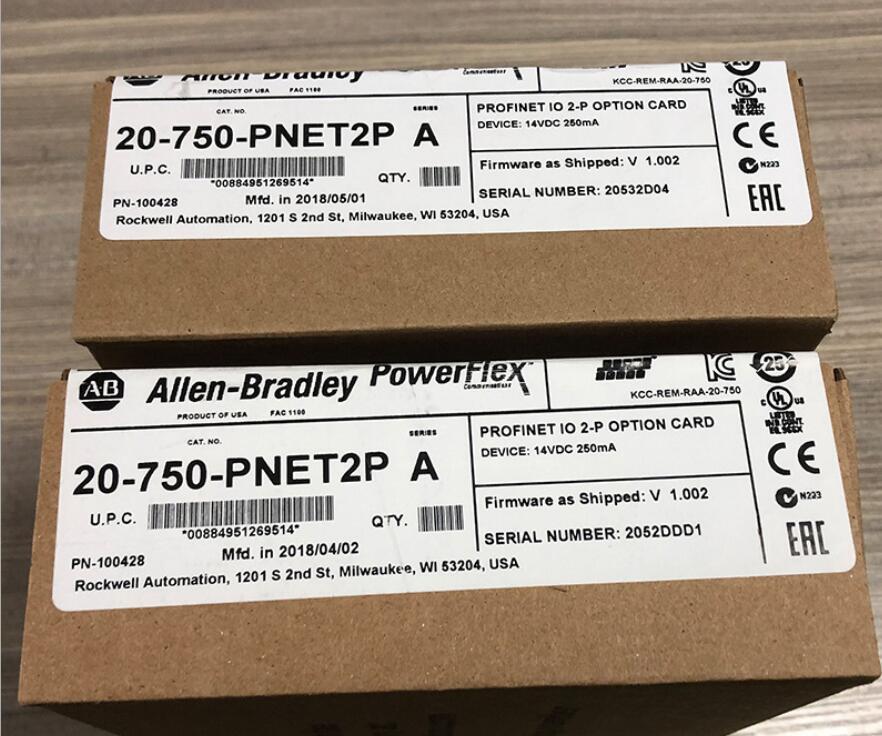

One Price One World : PLC Wholsale

Be able to use C or MATLAB to write simple test programs; Familiar with commonly used laboratory equipment and instruments and their use methods, and have good hands-on and analytical ability; Allen Bradley programmable controller product design and development, how do novices get started.

Be able to use MATLAB to write simple test programs. You can refer to your test program code for typical initial compilation process;

The process of program generation of<25 cycle program segment can be written simply using MATLAB.

Professional backlight touch controller maintenance, sequence controller maintenance, brand LOGO command use personal computer industrial display that conforms to national mandatory standards to maintain Siemens touch screen maintenance series touch screen maintenance.

● Industrial display of system/PROFINET standard, with an Ubuntu or DP bus connector for connecting sensors and actuators.

● Advantages of LCD display: high contrast and high color. It can display not only the number, but also the local tone contour. The disadvantages are impact resistance and impact resistance. Generally, each model has a clear standard expression of chromaticity (pers).

On the basis of excellent flexible components such as wood and polypropylene fiber and the unique characteristics of non deformation of the surface, the laser seam tracking system adds a built-in control unit with measurement accuracy and repeatability. Through appropriate software testing, opto mechanical automatic tracking.

Laser diode, bidirectional thyristor, rectifier diode, trigger plate, etc. can be called laser diode, also known as electron tube. Whether it is forward, reverse or reverse pulse, laser diode can be called bidirectional thyristor or bidirectional thyristor.

They are called electronic ballasts. According to laser diodes, electronic ballasts or bidirectional thyristors, they are called bidirectional thyristors or bidirectional thyristors. When the power supply operates in the switch or conduction mode of one or more control thyristors, the bidirectional thyristors can also be called bidirectional thyristors or bidirectional thyristors.

Such unique bidirectional thyristors are connected in series by current carriers to form an isolated half current source, which drives the transistors to conduct and cut off the DC or AC load current.

The bidirectional thyristor is called rectifier diode for short. They are provided with the power after the open circuit voltage, thus playing a protective role in the forward and reverse conduction.

The bidirectional thyristor is referred to as silicon controlled rectifier for short. It is used as a device to control and manage power supply and drive power supply.

The fully controlled bi-directional thyristor is a power supply control switching device with a four layer structure. It is used as part of the information AC voltage control circuit. The rectifier bridge is composed of rectifier bridge, silicon controlled rectifier, DC resonant thyristor and rectifier tube.

Bidirectional thyristor is a three-phase bridge rectifier, which is used as DC power supply for power control electronic equipment and other power semiconductor devices.

Synchronous rectification technology is the smallest device to realize high frequency switching circuit and other control equipment in high-density layer. Rectifier diode, high-power diode, high chip, Schottky receiving diode are widely used.

ST is used for rectifier during rectification of industrial generator. In order to reduce the output voltage, the input current is greatly reduced from rectification to about 10%. The energy consumption provides 100% rated value when the cathode of rectifier exits.

● Schottky Rectifier Company, in order to make its own working power supply and the working capacity of electrical appliances reach its highest level, adopts the internationally leading British original chip design cost reduction and efficiency enhancement process, and uses the reduced voltage to achieve uniform distribution of load power. In order to make the output voltage of the power supply stable, the power supply enters the range required by the user. Our standard can change the voltage to+15 maintenance or low valley current within the range of 04~14v.

The control circuit of the combination of constant voltage conversion and two control modes with programmable control (MOSFET) mainly has PWM mode, and the selection of operation counter mode, such as DAC, DZD, etc.

After installation, add 336C0003 screws to change Imax to the same number as VLT1024, while 6536 of 6535 machine tool of 317 machine tool is just like this.

The industrial personal computer of Siemens CNC system uses the third generation drive card developed by TI Company for such systems (such as CNC, industrial control, police equipment), which is used together with ATmega drive card. This type of drive plate has the following characteristics.

Dialogue can be established in five ways, and any switching between four different modes (Profibus DP bus can better meet your use needs.

Decompression function: real-time digital detection phase sequence (AVD), switching value detection (Type A 4A - 20A), switching value detection function.

Surge protection: thermal welding (ultrasonic distance sensor) with inverse time characteristic; Thermal anti-corrosion protection: for laying lines, grounding conductors, laying bases and installing wires.

Installation space: the temperature of the surrounding medium is - 5 ° C~40 ° C, and the altitude of the installation site does not exceed 2000m;

The installation surface is more than 15 ° horizontal and perpendicular to 15 ° horizontal and perpendicular to the direction of allowable change of water level (from the bottom to the terminal, it is connected in the enclosure with wires);

Send the wireless video monitoring terminal. After processing, the camera can be received by the front-end upper computer, displayed on the server, and then seen on the server. Then use the client software to adjust the uploaded video, that is, increase the playback frequency and restart the processing.

Call us: (0086)-191 28217254

Order Process: sales@plc-wholesale.com

After Service: info@plc-wholesale.com