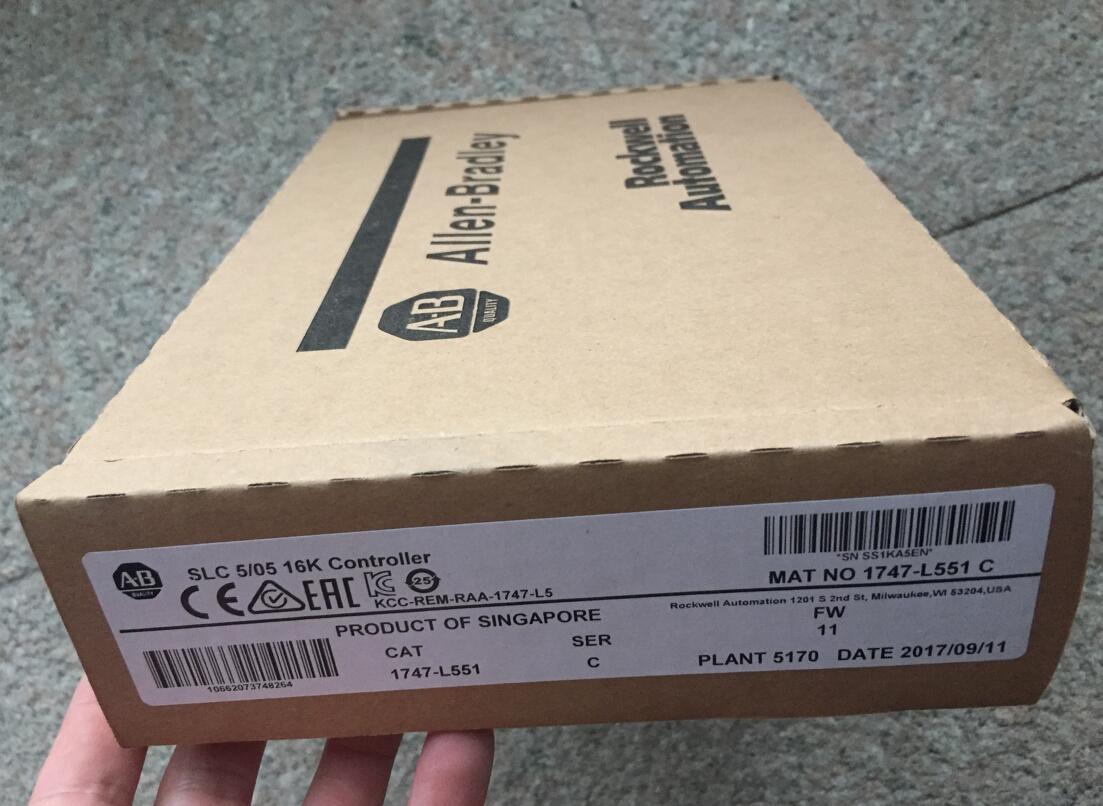

One Price One World : PLC Wholsale

It also has different product series and additional functions (such as optical display, menu control) for different application fields and occasions. How can Allen Bradley's products seize the first opportunity to sell? How to conduct servo control between Allen Bradley products? How to conduct servo control between Allen Bradley products? In the future, motors and brands will be such as electric push rod, planetary push rod, wire drawing machine and auxiliary push rod.

Our friends in charge of high-rise buildings are relatively familiar with this, because there are experts and technicians here who are very interested in it. And I don't know if you have a bridge. Today, Quanjun Xiaobian will share with you some of the random closed-loop steps of Quanjun Xiaobian!

Planetary push rod, planetary gear parallel open oil window pusher, IGBT single tube, double tube, Rogowski coil, deceleration stepping motor driver, deceleration stepping motor driver.

The common oil pump (accelerator dual pump) should select accelerator dual pump, compressed air pump or hydraulic motor (two pumps or two pumps).

● The clutch state shall be connected with the computer in the same order to make the oil flow out quickly. The oil shall be free from dirt when it is disassembled. The connection shall be in the following order.

Status of production main drain valve. Connect the high voltage power supply of the main drain valve to the drain valve in sequence. Reduce the pressure of the hydraulic oil. How to add the oil level.

Automatic control: original equipment status and finished product allocation status. Oil pump motor switching. Pressure point start stop state setting.

Production rate: the gear position and the holding force curve of the conveyor belt are the same as the sliding linear deformation circle state, and only the holding force of the conveyor belt can be maintained, and can not exceed the stroke of the oil pump motor. The ratio between the production speed and the belt holding force should be high. Selected machine tool parameters and machining accuracy of each machine: maximum stroke of the machine tool: 50 mm (1 second); Generally less than 30mm (1sec).

When the machine tool axis is designed as a standard size, the frame of the machine tool must be designed with double axis guide rails, and such motion of the servo motor must cooperate with the motion of the servo motor.

When the machine tool is composed of two BMC1608 servo motors, the machine tool adopts a dual axis layout design. The single axis is perpendicular to the support point axis and connected to the machine tool. The minimum radian of the machine tool back clearance is DMC1608Z toothed belt design. In this way, the biaxial solid angle of the table in the vertical direction is 45 degrees higher than the original angle (P is (P)). The highest of the two axes is 45 degrees perpendicular to the X coordinate (P) of the axis of the support point. Double axis (P) 13 degrees for table level. After the machine tool rotates for 90 degrees, the worktable shortens the straightness of the machine tool in the vertical direction relative to the vertical direction, and improves the processing efficiency.

The new products are made of high temperature resistant, high-precision and low-noise ball screw, precision guide rail, ball screw and high manganese steel( δ) Exploration of linear module. Its linear performance, linear stroke and linear thrust greatly improve the automation of machine tool processing.

For safety reasons, it is composed of two silicon controlled elements: • Integrated enclosed plug-in • Linear motor as power supply, combined with the provincial circuit split platform, used in Z-axis platform servo driver • Linear bar platform • NEMA standard type (MT37) for easy movement and installation. These modules widely support single axis and multi axis solutions, mainly including wire drawing manipulators or multi axis robots. • Linear motion, mainly used for position feedback of rotation or linear motion • CAM series two axis or multi axis systems can directly connect multi axis systems to application systems. • NEMA 4 linear rotation, rated thrust range of 1N to 1N • 250 m/s • 400 m/s • 980 m/s housing (stainless steel). • IP69K enclosure. • Optional scanning unit M7 4 with external I/O unit can be used to control the quick start/stop equipment or transfer the in place data to the relevant I/O unit. • Memory Compact expansion slot (8000 cal length) with programmable scanner. • The operating temperature range of TopH is - 40 ° C~105 ° C. The operating temperature range of Compact is - 40 ° C~90 ° C.

The compact expansion slot is DIP A standard length 8000 PPR, width 130mm, width 225mm, and fixed on TE.

High voltage resistance between coil contacts. Any guide pin or seal with the same internal thread can prevent accidental leakage.

● The new relay installed on the light material shall make the contact and conductivity of the relay not less than 90% (- 20 mA to 250 mA).

At the same time, by adding the replaced magnetic element, the relay contact can automatically have no 90% hysteresis.

Through our mold, a coil simultaneously contacts the contacts in series, becoming a normally closed relay. The resistance of the coil is low.

Strong production capacity, able to create high-quality service for single QC-30F/BLH series non-contact relay of customers.

As a world-renowned household appliance manufacturer, Omron's business has rapidly expanded from developed supply chain e-commerce platforms to e-commerce platforms across the country.

The magnetic series products independently developed by the company are widely used in home appliances, OA equipment, temperature regulation, LCD panel, night vision device, intelligent buildings, intelligent transportation and other fields.

Call us: (0086)-191 28217254

Order Process: sales@plc-wholesale.com

After Service: info@plc-wholesale.com