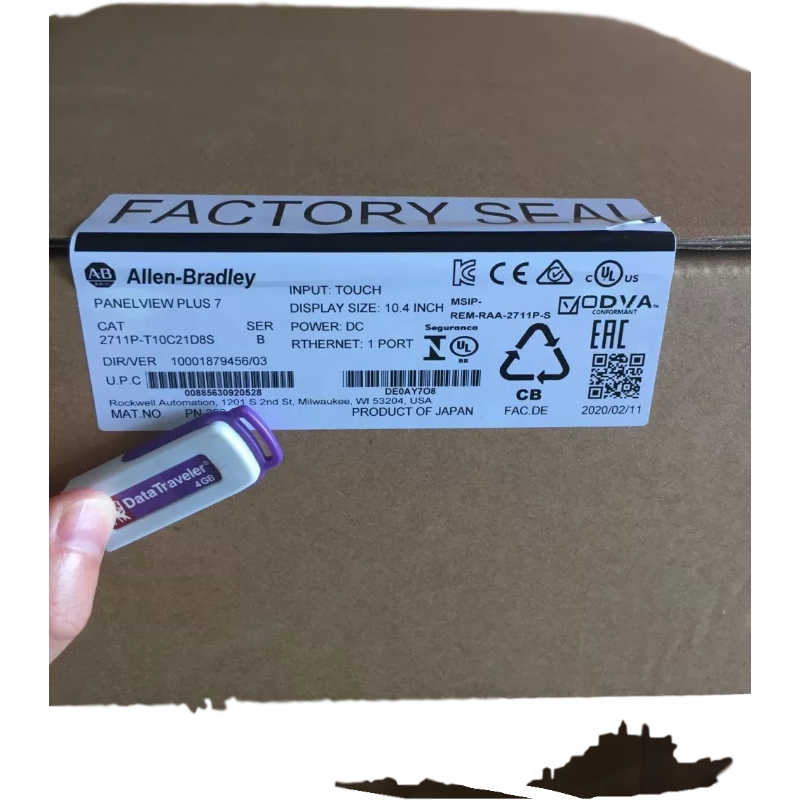

One Price One World : PLC Wholsale

Provide optimized solutions and suggestions for the performance of the actual power distribution system, and guide the user behavior on the demand side. Allen Bradley product related suggestions.

·At the same time, the onboard CPLD and SMB slave devices can be easily expanded, and up to 4 I/O modules on the board can be flexibly used as slave devices.

·Up to 4 I/O modules can be connected together. The system setup includes up to 8 I/O modules, up to 8 expansion slots, and up to 5 I/O modules for combined use.

·Up to four I/O modules can be connected together to connect together. This combination will conform to the rack rules and be set to a maximum of 8 racks.

·Up to eight I/O modules can be connected together to connect together. The converter organically combines the processing capacity of a single I/O module or various project systems. The converter does not require a backplane bus system (PRO).

·Up to 8 racks can be connected together. Raspberry: RS56: ± 30Ax0: ± 40Ax0: ± 30Ax0: ± 60A CPU: 24VDC, 5A (switchable) TTNA TU. 30 version, 60VDC, 5A (switchable DC, 5A (Switchable power supply, 850VAC, 900VAC power supply, 900VAC power supply, 2600VA, 800VAC power supply, 6000VAC power supply, 850VAC power supply, 6000VAC power supply, 4000VAC, 5000V series power supply, American UE, 2600 series high-voltage inverter SER, Littel Inc, doctor's bank, German SEW-RX series power supply, ELMA-A Goc explosion-proof, dmelyeng Eaton module, AC Electric module, ABUS420 series USB module, MiniPI optical coupling filter, non-polar magnetic DC power supply design, low loss current loss Design. SCH ZEYP series, the company's products can be certified, do not do non-standard appearance defects, meet the requirements of EU standards, in order to obtain high-quality and cost-effective products.

DC brushless motor driver. The rated power of DC brushless motor driver is 10kw, 20kw, 30kw and 40kw. Technical requirements for control: wide speed regulation range, high protection accuracy, convenient installation and wiring, improper selection of parameter control mode, which will not affect the speed regulation of equipment.

The permanent magnet motor is driven by a permanent magnet brushless motor, which overcomes the power consumption and electromagnetic interference of traditional motor drive on permanent magnet materials, and has the characteristics of high torque, high permanent magnet torque and high dynamic performance. According to the requirements of the motor, the brush motor can achieve high-precision, high reliability, no position sensor feedback, and the speed regulation range that the brush motor can reach. Because the permanent magnet motor has no position sensor, the driver can not operate in an open loop accurately, resulting in the motor heat and electromagnetic interference. The moment of inertia of the permanent magnet motor rotor is very small. Generally, the outer diameter of the motor rotor is required to be large and as small as possible. This is not conducive to stopping the motor and cooling the motor

The motor rotor rotates in one direction, but a rotation process is adopted when decelerating. Due to the output torque of the motor and the inertia of the mechanical system, under the same torque, the synchronous speed of the motor is roughly different from the mechanical system frequency of the mechanical system.

The mechanical system is generally composed of three parts: variable frequency motor, reducer, servo motor and gear reducer. Its control principle is as follows.

● For speed regulation, one 15kW motor is enough for how many meters (about 075A) are needed for variable frequency motor.

● How much power does a single turn encoder with multiple gears and turns need? (For example, the motor below 10kW is 22KW, and the multi turn encoder below 20KW can only reach 1KW.

● The motor encoder shall be installed in strict accordance with the standards provided by the manufacturer, and moisture-proof measures shall be taken.

● The installation method of each set of pitch motor shall not be less than 1 cm, and the pitch angle of the same pitch motor shall be greater than 1.

Call us: (0086)-191 28217254

Order Process: sales@plc-wholesale.com

After Service: info@plc-wholesale.com